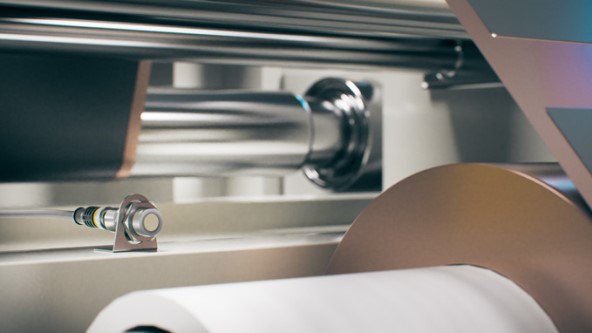

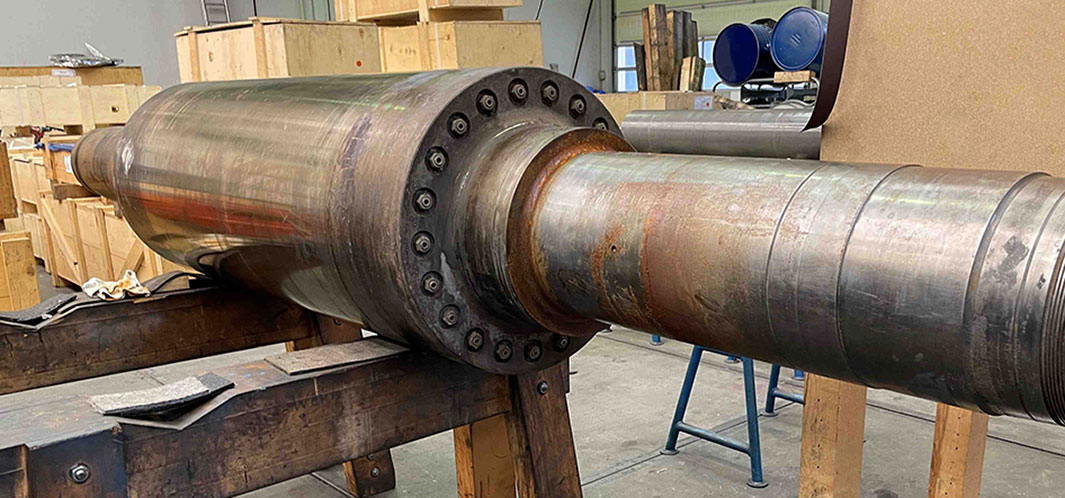

By reconditioning we mean the repair of your rolls, shafts and other components. It is a sensible replacement for a new acquisition. By reconditioning worn barrel surfaces or bearings seats, or by replacing entire journals, the roll or other rotationally symmetrical components are brought up to date. Your advantage is the modernization of your system with an increase in productivity, but a significant lower cost.

|

Measuring of TIR and geometrical shape with automatically measuring systems |

|

Grinding of rolls at ambient temperature |

|

Hot grinding of rolls at operating temperature |

|

CNC-grinding cylindrically or with crown, hollow, special shapes |

|

Grinding in mounted bearings and housings |

|

Coating with e.g. chrome, nickel, ceramics, tungsten carbide and anti-adhesives |

|

Polishing of chrome plated rolls up to mirror quality |

|

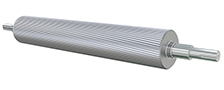

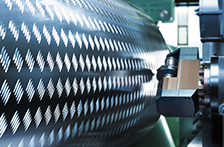

Fluting of rolls |

|

Milling of bulb and checker designs |

|

Three-dimensional milling on 5-axle-machining-centres |

|

Internal cleaning and rinsing of rolls |

|

Dynamically balancing in two-planes |

|

Repairing of bearing seats by means of chrome plating or with thermal spray coatings |

|

Repairing of journals and changing of journals |

|

All kinds of repairs of rolls |