Rollers for use

along the value chain.

along the value chain.

The global importance of batteries and accumulators is greater than ever in view of social and technical change (EV, energy production and -transformation, etc.).

As a roller manufacturer e.g. for electrode and separator foils, we contribute to efficient, cost-effective and reliable battery production processes.

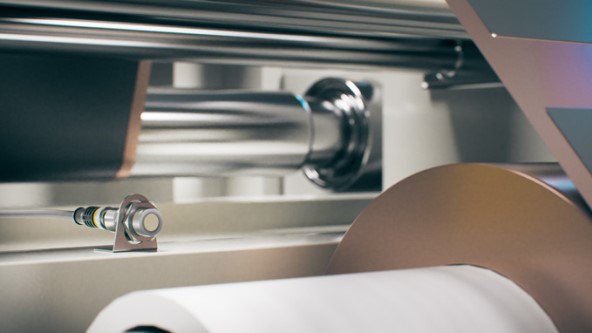

Our rollers are used in various steps of complex battery production to process even the thinnest materials such as lithium, aluminum or copper. The uniformity of the foil thickness and the compression of the electrode coatings are the key to a long-lasting battery.

Also our coating and application rollers and calander rollers are used for this purpose.

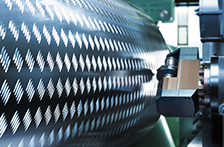

In order to meet the diverse requirements of the battery foil industry, we draw on a broad portfolio of materials. In addition to proven chilled castings from our own foundry, we offer a wide range of forged steels (42CroMo4, 86CrMoV7, etc.), composite steel castings and high-chrome materials.

Besides new rollers we have specialized in recoating and regrinding rollers for battery foil production for many years.

Coating

Uniform coating or dry coating during electrode production is performed efficiently and reliably by our

and coating rollers efficiently and reliably to the highest quality standards.

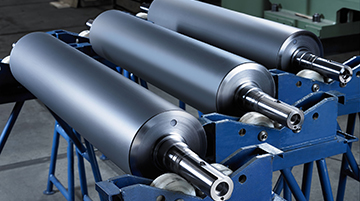

Compaction

The thinnest films are compacted by evenly and precisely by our calender rollers with precisely defined line pressure

so that battery films with precisely defined thicknesses and microstructures are and microstructures.

We are happy to help you!

Would you like to find out more and more about our rollers and services in the field of electrode and

separator films? We look forward to hearing from you and will be happy to help.