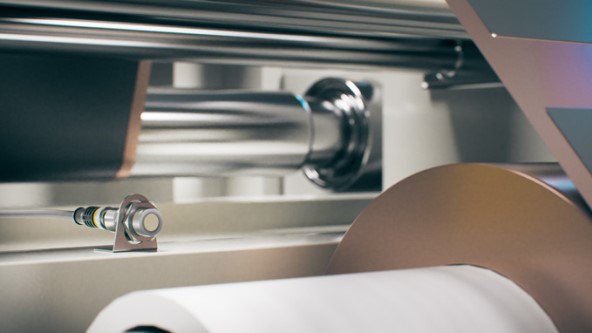

We are at your side as a reliable partner. Service is very important to us. Whether it is about counseling or it is about supporting our customers in the project phase. Our many years of extensive experience in a wide variety of industries and the numerous possible applications of our rolls offer our customers and their components a real added value.

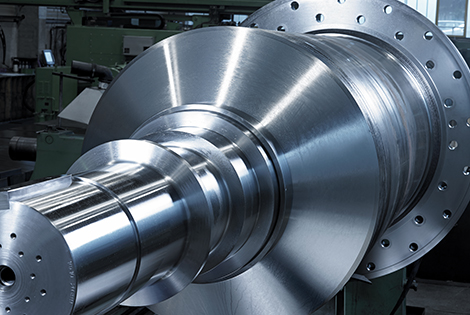

Turning

Multi axis machining

Others

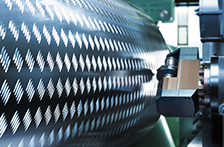

Pattern design

Deep hole drilling (eccentrically)

up to Ø 40 x 2,200 mm

Contour machining of holes

up to Ø1,600 mm x 4,200 mm in depth

polishing and lapping

burnishing

honing

from Ø 150 up to 700 x 8,700 mm

all types of machining on a milling and boring machine

coating with chrome, ceramic, hard metal, rubber and polyurethan

Fluting of rolls

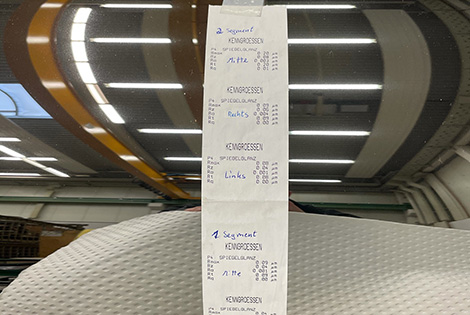

Measuring of TIR and geometrical shape with automatically measuring systems

Dynamically balancing in two-planes

Polishing of hard coated rolls up to mirror quality

|

Grinding of rolls at ambient temperature |

|

Hot grinding of rolls at operating temperature |

|

Grinding in mounted bearings and housings |

|

Coating with e.g. chrome, nickel, ceramics, tungsten carbide and anti-adhesives |

|

Three-dimensional milling on 5-axle-machining-centres |

|

Internal cleaning and rinsing of rolls |

|

Repairing of bearing seats by means of chrome plating or with thermal spray coatings |

|

Repairing of journals and changing of journals |

|

All kinds of repairs of rolls |