Technical data

Inquire now

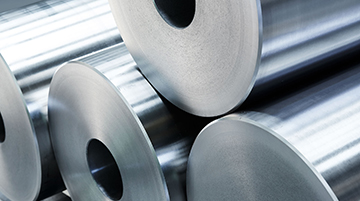

| Industry |

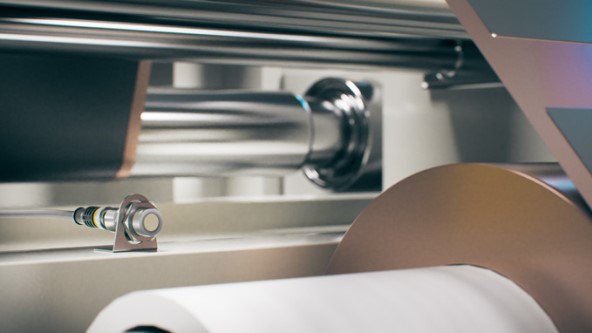

oil seed industry, animal feed production und production of cornflakes and oat flakes (cereals) |

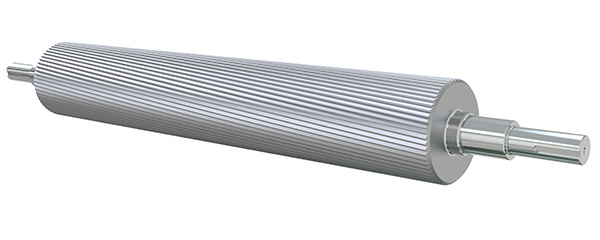

| Common diameter |

400 – 1,000 mm |

| Common roll body length |

600 – 2,500 mm |

| Material |

static casting TR 100 – TR 120, |

| Design |

solid, with centre bore, |

| Journals |

made from steel – shrunk in, |

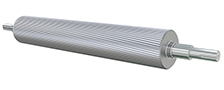

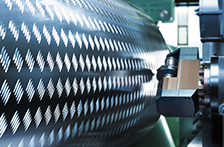

| Surface |

cylindrically ground or ground with crown, fluted |

| Special features |

blanks available |