Technical data

Inquire now

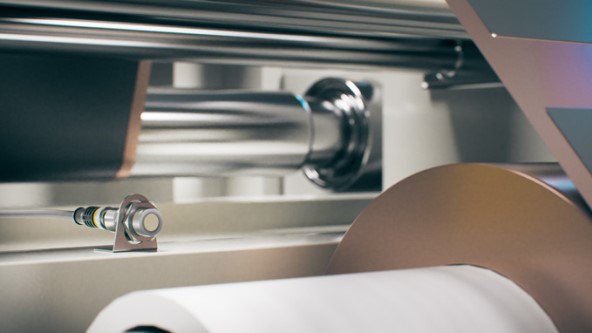

| Industry |

PVC-foil production |

| Common diameter |

300 – 875 mm |

| Common roll body length |

600 – 4,500 mm |

| Material |

chilled cast iron Tuk 00 – Tuk 30, |

| Design |

cored, peripherally drilled with plug or ring sealing |

| Coating |

without coating, chrome, tungsten carbide |

| Surface |

cylindrically ground or ground with crown, |

| Precision |

TIR and geometrical shape 0.002 mm |

| Special features |

hot ground for best precision at operating temperature |

Technical data

Inquire now

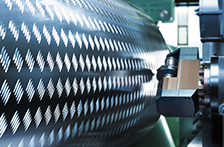

| Industry |

rubber and tire production |

| Common diameter |

300 – 875 mm |

| Common roll body length |

600 – 3,000 mm |

| Material |

chilled cast iron Tuk 00 – Tuk 30, |

| Design |

cored, peripherally drilled with plug or ring sealing |

| Coating |

without coating, chrome |

| Surface |

cylindrically ground or ground with crown |

| Precision |

TIR and geometrical shape ≤ 0.005 mm |